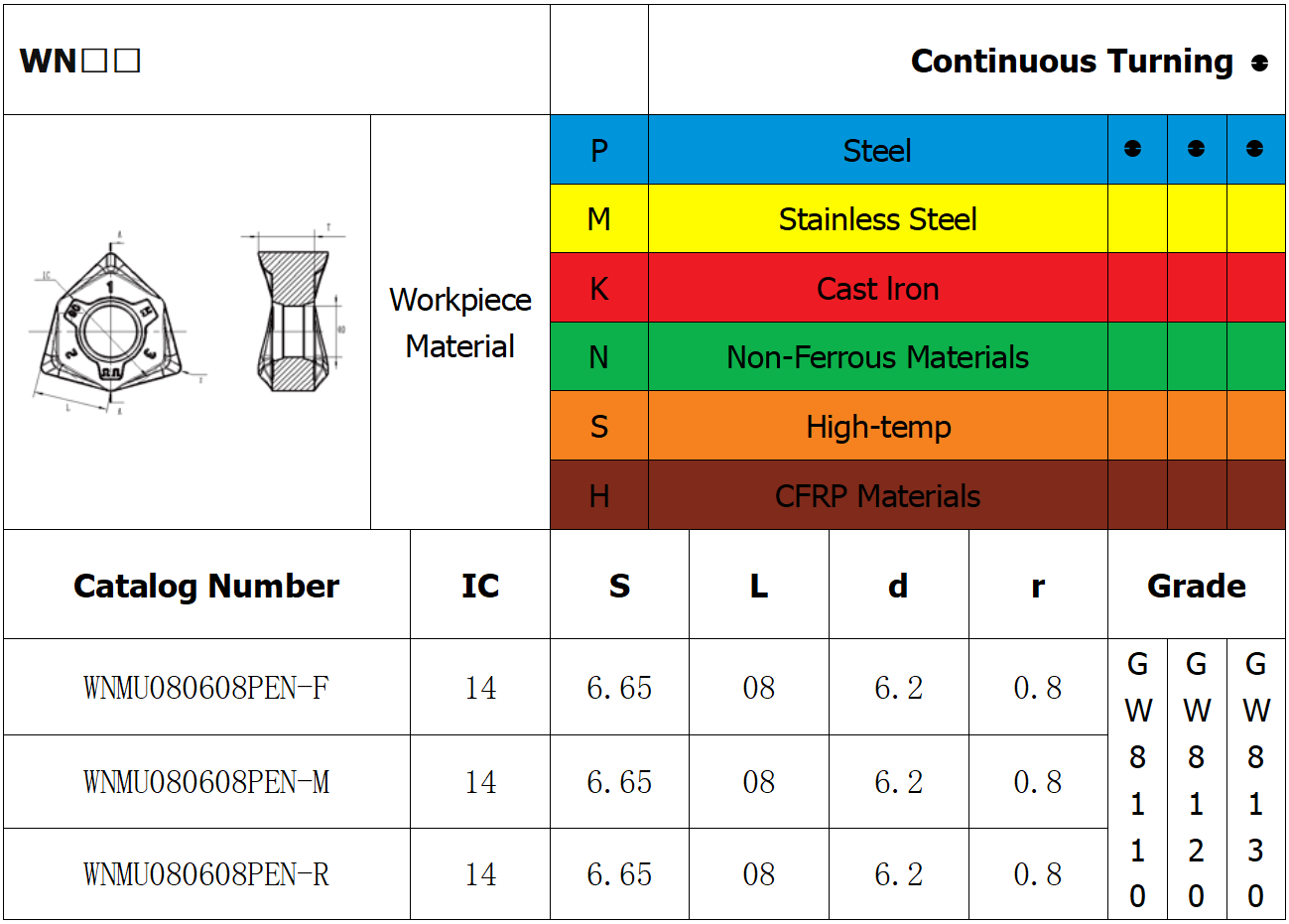

WN▢▢

-

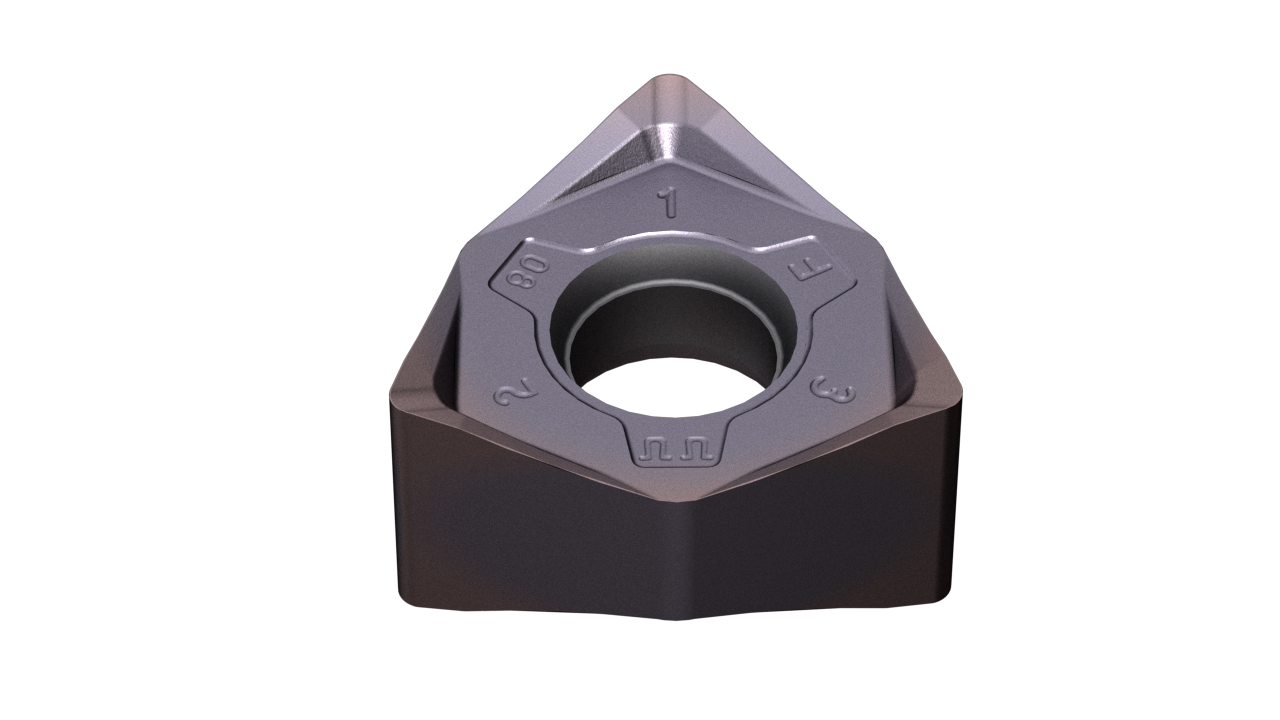

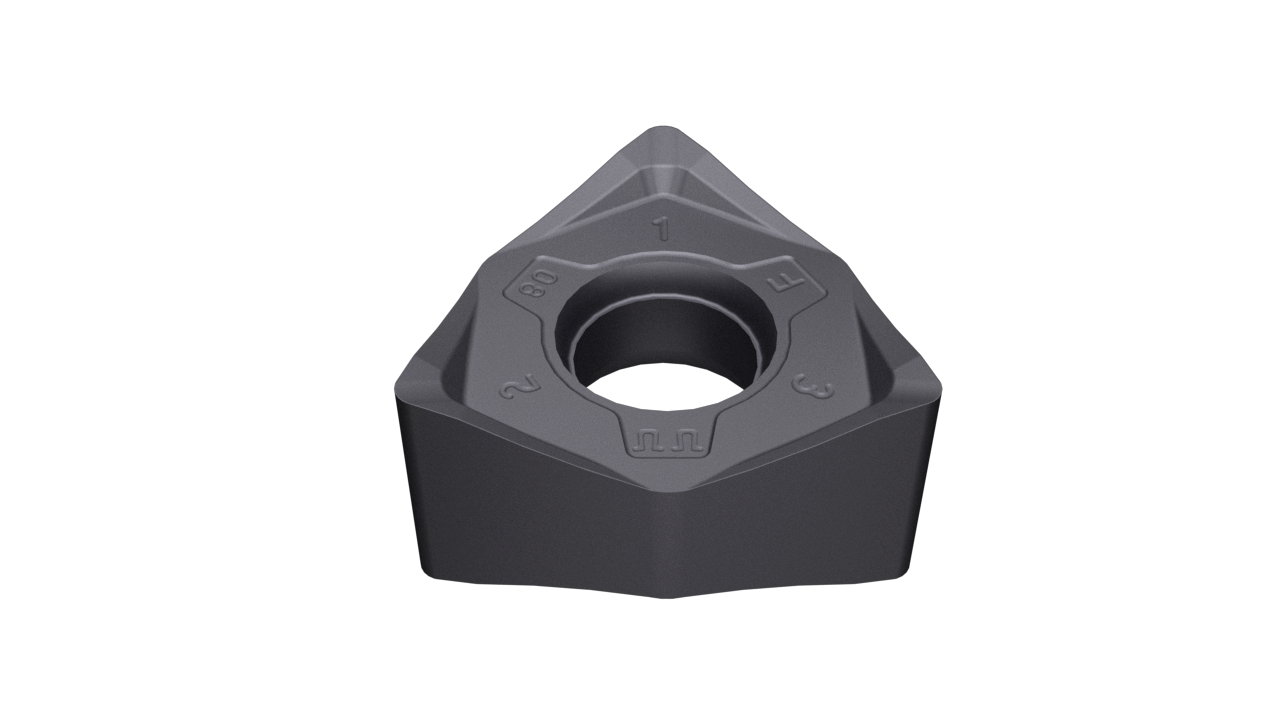

Detail

Milling inserts and grades for steel

Modern milling insert grades for hardened steel are designed for productive machining at realistic costs per part. Find the right insert grade for your operation here.

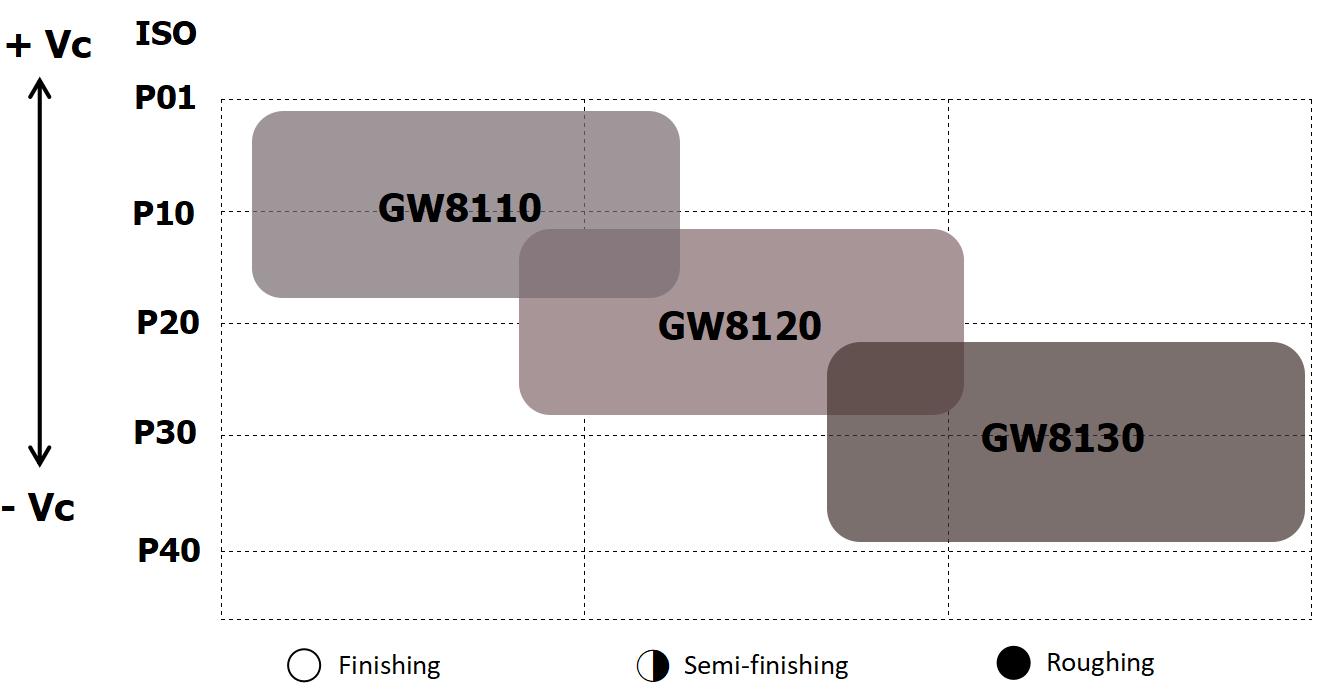

GW8110、GW8120 and GW8130

Grades GW8110、GW8120 and GW8130 with its high wear tesistance and fracture resistance , this grade can withstand long periods of time in cut and is suitable for machining high hardness steel and hardened steel. Benefits

- First choice grade for hardened steel

- High cutting speeds

- Security and long tool life

Find your gradeOur steel insert grade assortment consists of coated carbide grades and uncoated cermets for various machining conditions.

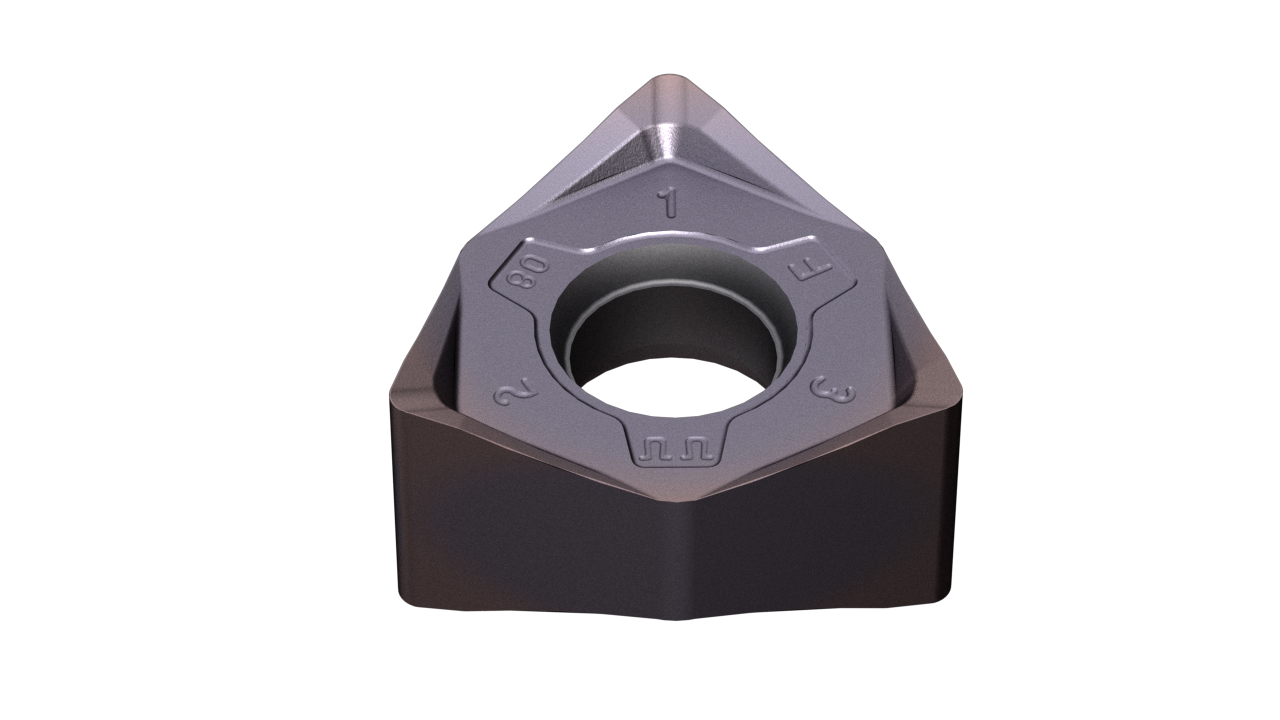

GW8110

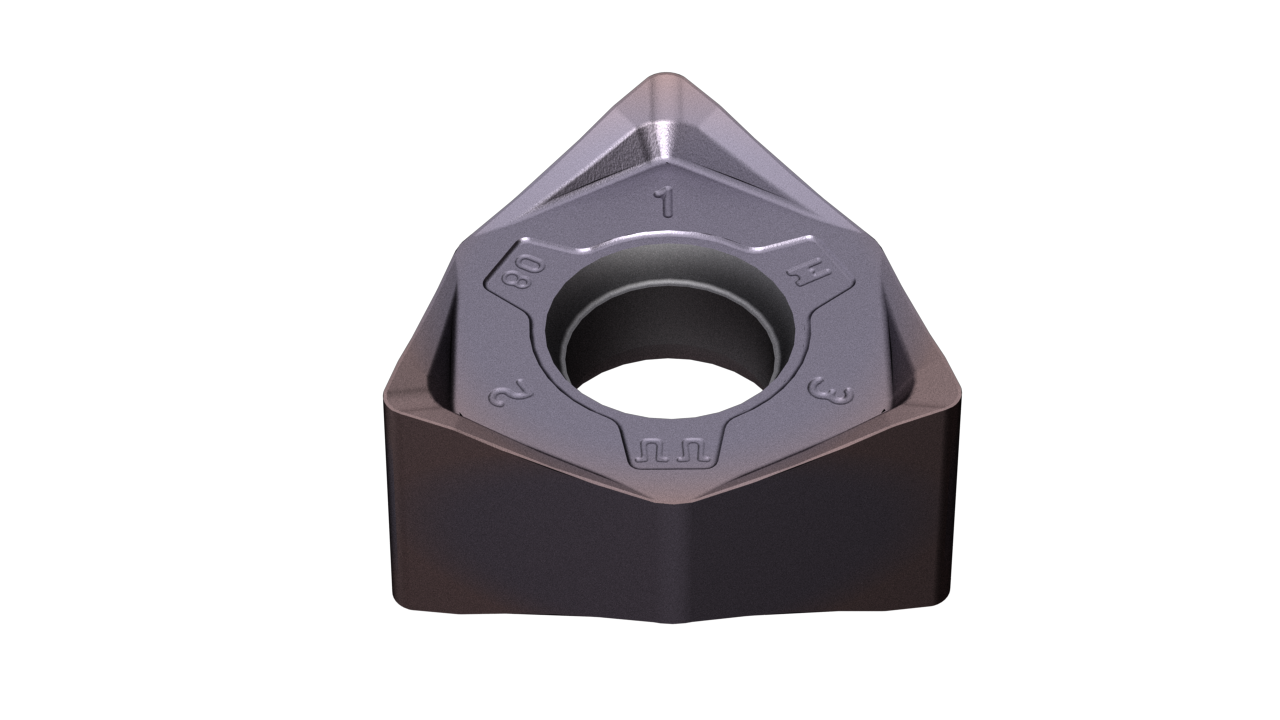

GW8120

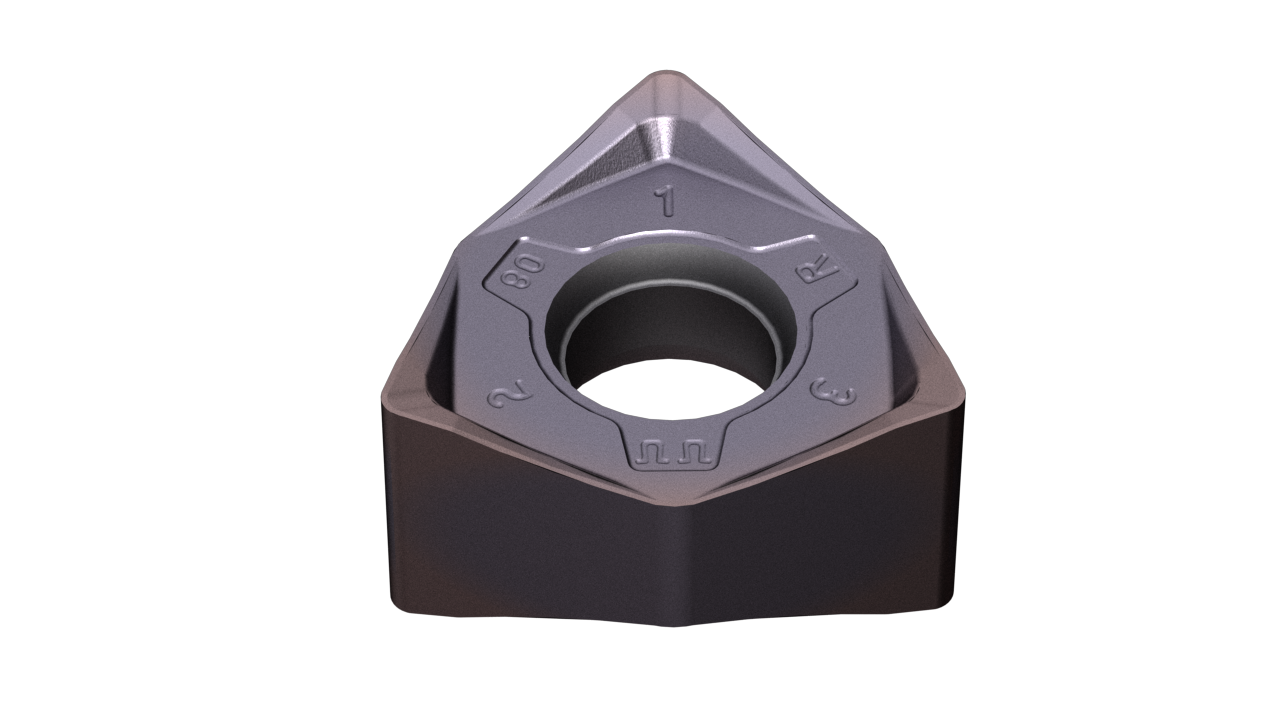

GW8130

• High-hardness fine machining grades.

• Featuring a fine-grained matrix, offer both high wear resistance and fracture toughness.

• Applicable to finishing and semi-finishing machining of steel components, stainless steel materials, and high-temperature alloys.• High wear resistance.

• Applicable to milling processes of steel and stainless steel.• High impact resistance and wear resistance.

• Suitable for semi-finishing and rough milling processes on steel components, stainless steel materials, and cast iron.

About Chip breaker

Chip Breaker

Illustration

Feature

Recommended Dosage

Feed rate

Cutting depths

F

·The keen-edged slot design ensures a brisk cutting action with minimal cutting resistance and excellent anti-adhesion performance; it promotes stable chip curling, allowing for smooth chip evacuation even at high feed rates, thus achieving superior surface finish quality on the workpiece.

0.1-0.3

0.2-2.0

M

·The universal slot profile ensures stable chip curling, facilitating smooth chip evacuation even at high feed rates, thereby contributing to a good surface finish quality in the machining process.

0.1-0.5

<5.7

R

·The roughing slot profile, with its robust structural design, is capable of handling a variety of harsh working conditions.

0.2-0.5

<5.7

-

Customer ReviewsNo comments

USD

USD