CN▢▢

-

Detail

Turning inserts and grades for cast iron

When selecting insert grades for cast iron machining, it’s important to understand the mechanical properties of the various types of cast iron. Find reliable insert grades for your cast iron turning operation that offer long tool life at a high metal removal rate.

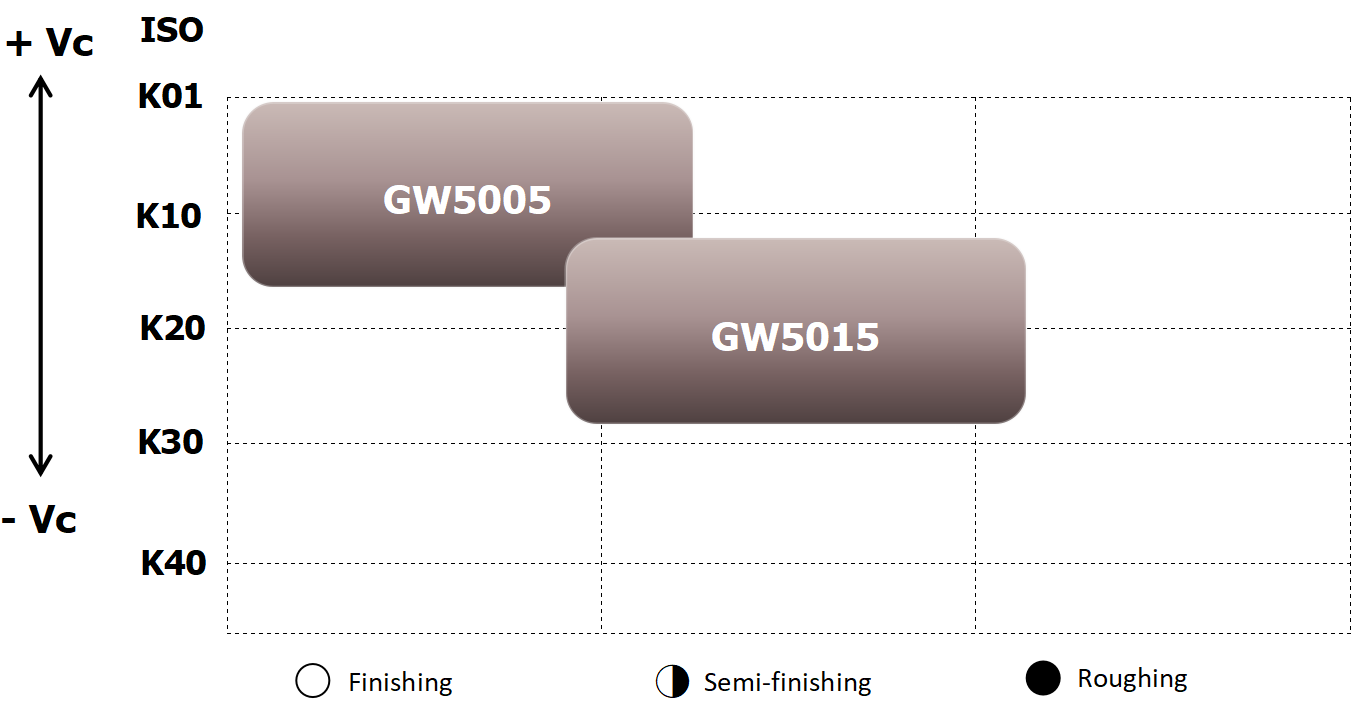

GW5005 and GW5015

The CVD-coated cemented carbide grade offers high flank wear resistance and is best for good to average machining conditions in all cast iron materials for continuous and interrupted cuts.

The GW5005 with High-speed continuous turning with high wear resistance and resistance to plastic deformation. Employing a thick TiCN plus a thick Al₂O₃ CVD coating, and after special surface post-treatment, it exhibits high wear resistance and high-temperature oxidation resistance. Suitable for high-speed machining of cast iron.The GW5015 with the substrate combining hardness and toughness, featuring high wear resistance and resistance to plastic deformation. Employing a thick TiCN plus a thick Al₂O₃ CVD coating, and after undergoing special surface post-treatment, it demonstrates high wear resistance and high-temperature oxidation resistance. Suitable for medium-to-high speed machining of gray cast iron and ductile iron, as well as turning and milling operations on various types of cast iron materials.

Benefits and features

- Resists flank wear

- Suitable for all cast iron materials

- Continuous and interrupted cuts

Find your gradeOur hardened material insert grade assortment mainly consists for various machining conditions. We also have complementary grades. Use the information below to find the right grade for your production.

GW5005

GW5015

• High wear resistance.

•Suitable for high-speed machining of cast iron.• High wear resistance and resistance to plastic deformation.

• Suitable for medium-to-high speed machining of gray cast iron and ductile iron, as well as milling operations on various types of cast iron materials.

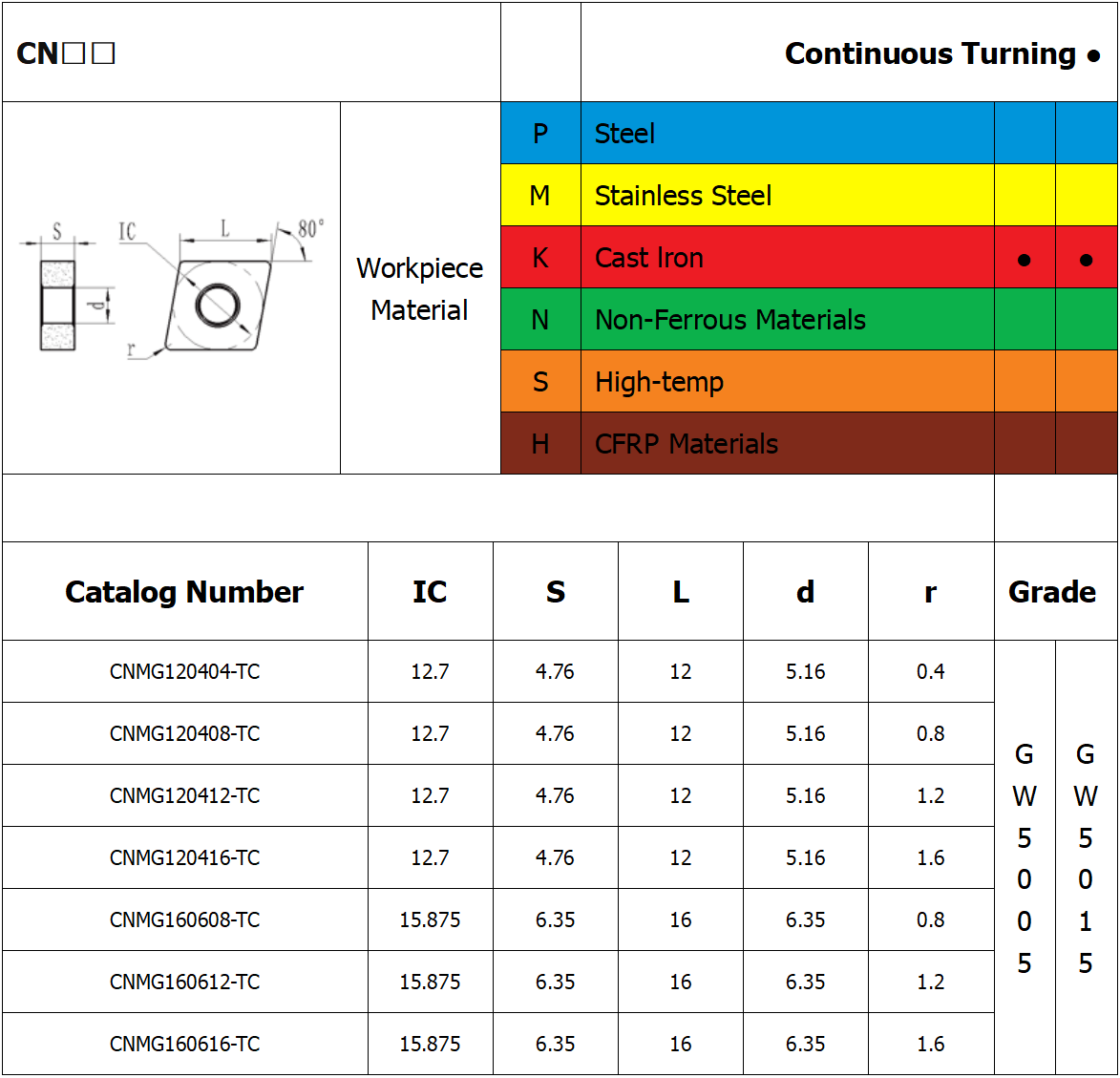

About Chip breaker

Chip Breaker

Illustration

Feature

Recommended Dosage

Feed rate

Cutting depths

TC

·General flute configuration, providing light and smooth cutting.

·Suitable for semi-finishing and roughing of cast iron materials.

0.1-0.3-0.6

0.05-2.0-6.0

-

Customer ReviewsNo comments

USD

USD