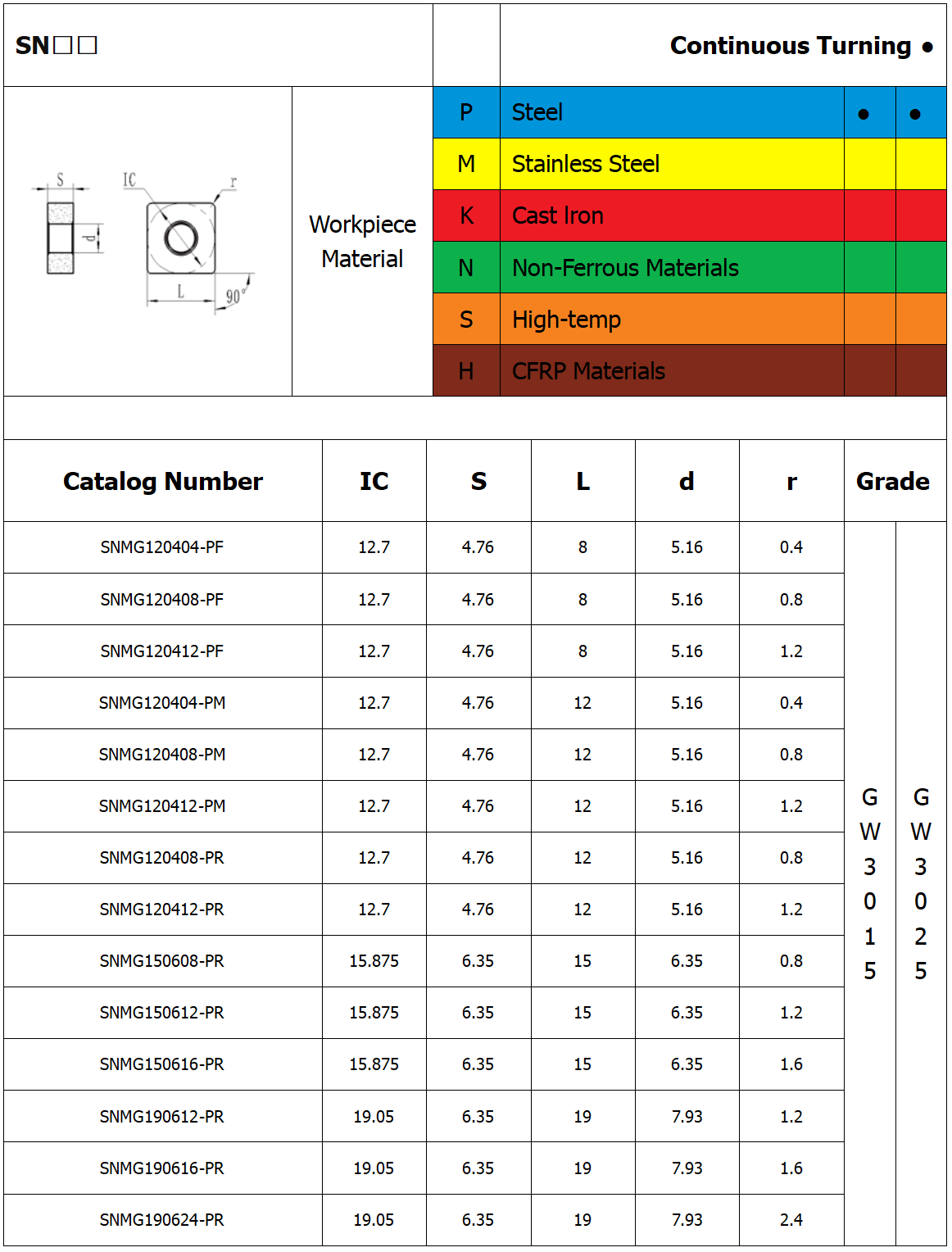

SN▢▢

-

Detail

Turning inserts and grades for steel

Whether you are looking for turning insert grades for unmanned production or custom-made components, we have reliable insert grades that offer a predictable tool life,high machine utilization, and the surface quality you need.

GW3015 and GW3025

The new generation steel turning insert grades GW3015 and GW3025 deliver all-round improved performance.They have a broad range of applications and are recommended for continuous and interrupted cuts. The first choice grade GW3015 offers improved wear resistance, heat resistance and toughness in a wide application range.Grade GW3025 complements GW3015 with enhanced performance when more heat resistance is needed.

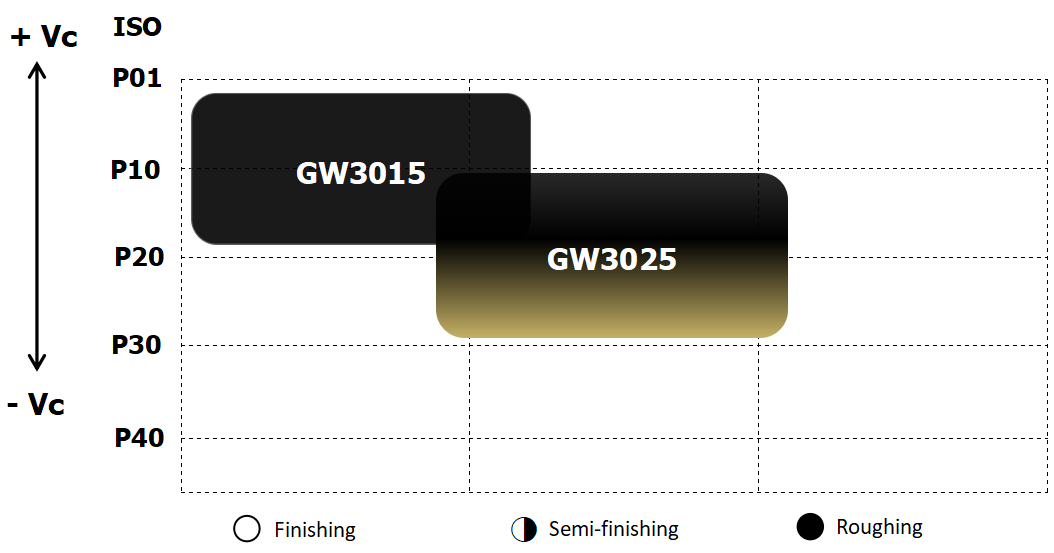

Find your gradeOur steel insert grade assortment carbide grades for various machining conditions. Use the information below to find the right grade for your production. Higher productivity (vc) means increased plastic deformation and crater wear resistance. Chipping resistance and edge line security are dependent on how stable the machining conditions are.

GW3015

GW3025

● Wonderful wearing resistance in continues turning.

● Preferred grade for steel finishing.●Excellent chipping resistance in continues and light interrupted turning .

● Preferred grade for steel semi-finishing.

About Chip Breaker

Chip Breaker

Illustration

Feature

Recommended Dosage

Feed rate

Cutting depths

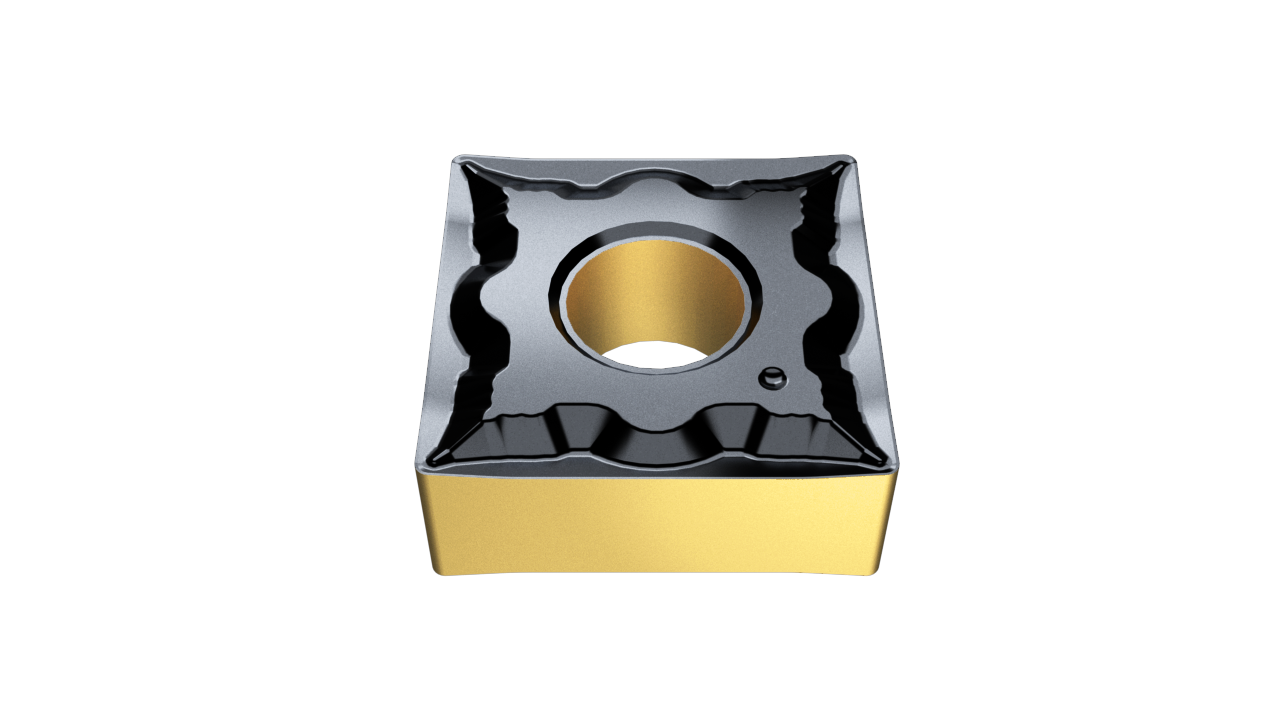

PF

·Featuring a dual rake angle and relief angle design, it ensures light and efficient cutting with excellent surface finish quality.

·When used with shallow depths of cut and low feed rates, it demonstrates superior chip breaking performance, with consistent chip curling that prevents scoring on the workpiece.

·Ideally suited for finishing operations on steel materials.

0.10-0.15-0.20

0.3-0.5-1.0

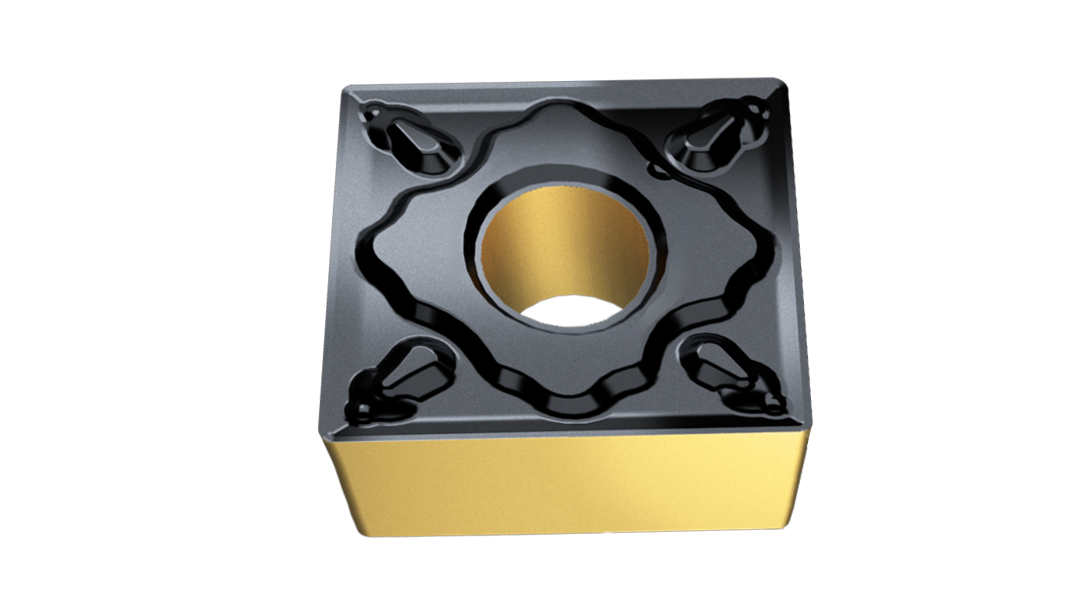

PM

·With a dual rake angle design, the cutting edge remains sharp, reducing cutting resistance and minimizing tool adhesion.

·The three-dimensional protrusion design at the tool tip effectively facilitates chip curling and breakage, providing ample chip room. This allows for smooth chip evacuation even during operations with larger depths of cut and feed rates

·It is particularly well-suited for semi-finishing applications on steel materials

0.10-0.20-0.30

0.5-1.0-1.5

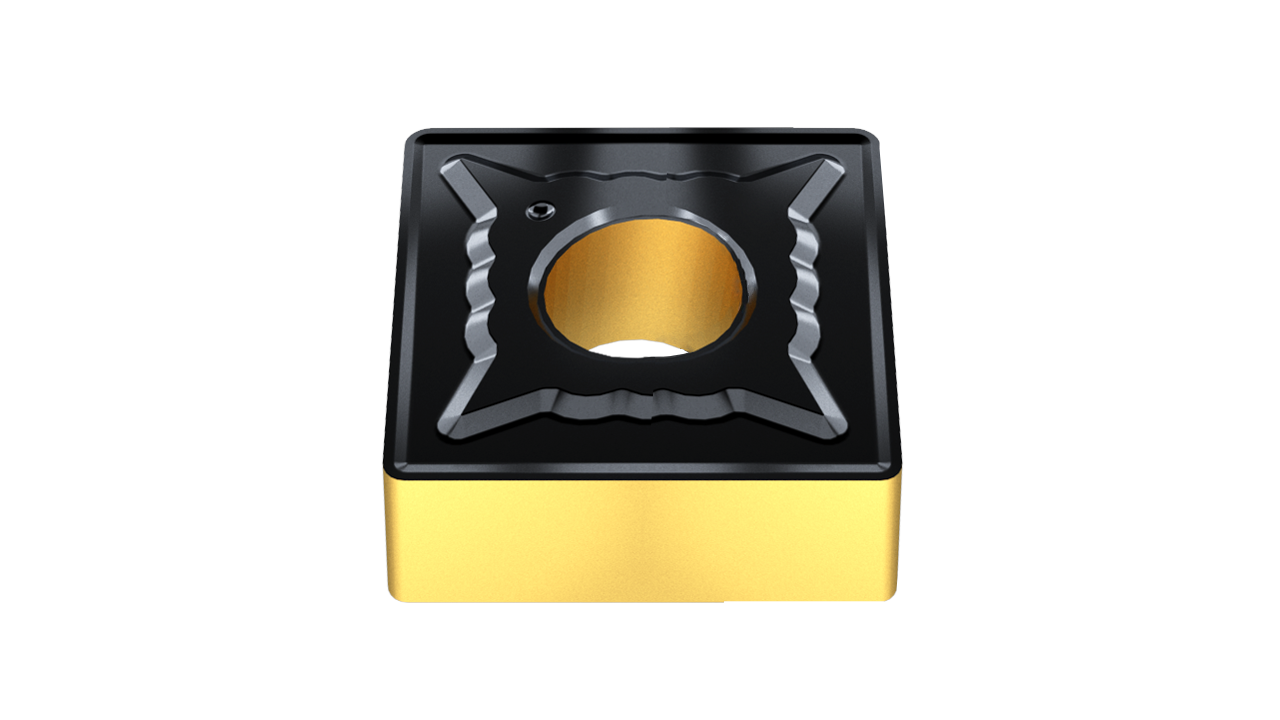

PR

·Equipped with a wide, dual-rake angle design, it offers low cutting resistance.

·Boasting a robust tool tip and a strong cutting edge with wide slot and shallow depth, it provides substantial chip capacity and effective chip breaking. Even at moderate depths of cut, chi curling remains optimal.

·Ideally suited for rough machining of steel materials.

0.10-0.20-0.30

1.0-1.5-2.5

-

Customer ReviewsNo comments

USD

USD