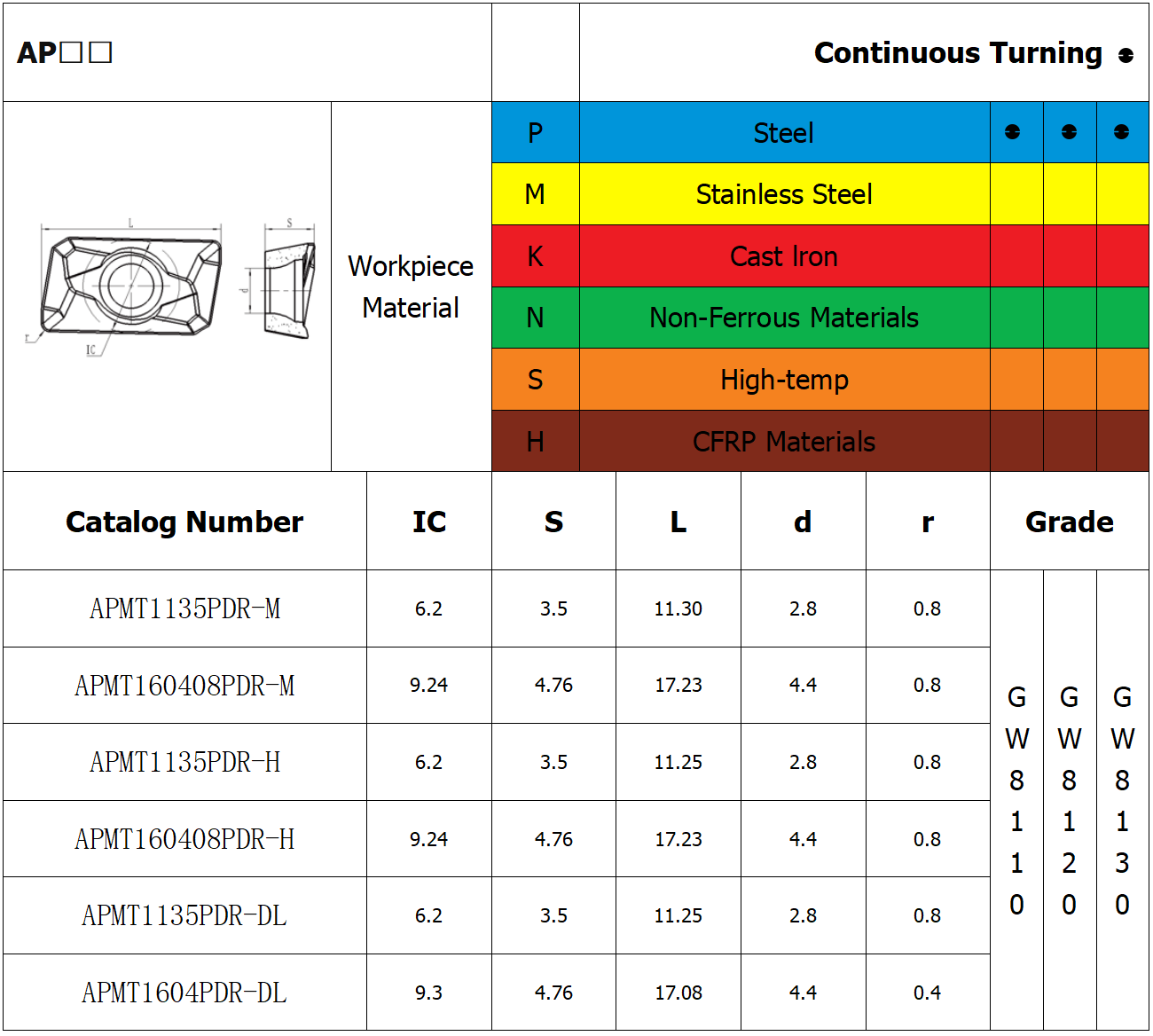

AP▢▢

This price is for retail. For bulk orders, please inquire via email.

Quantity

-

Detail

Milling inserts and grades for steel

Whatever your component or requirements for surface finish, find your coated carbide grades and uncoated cermets optimized for steel.

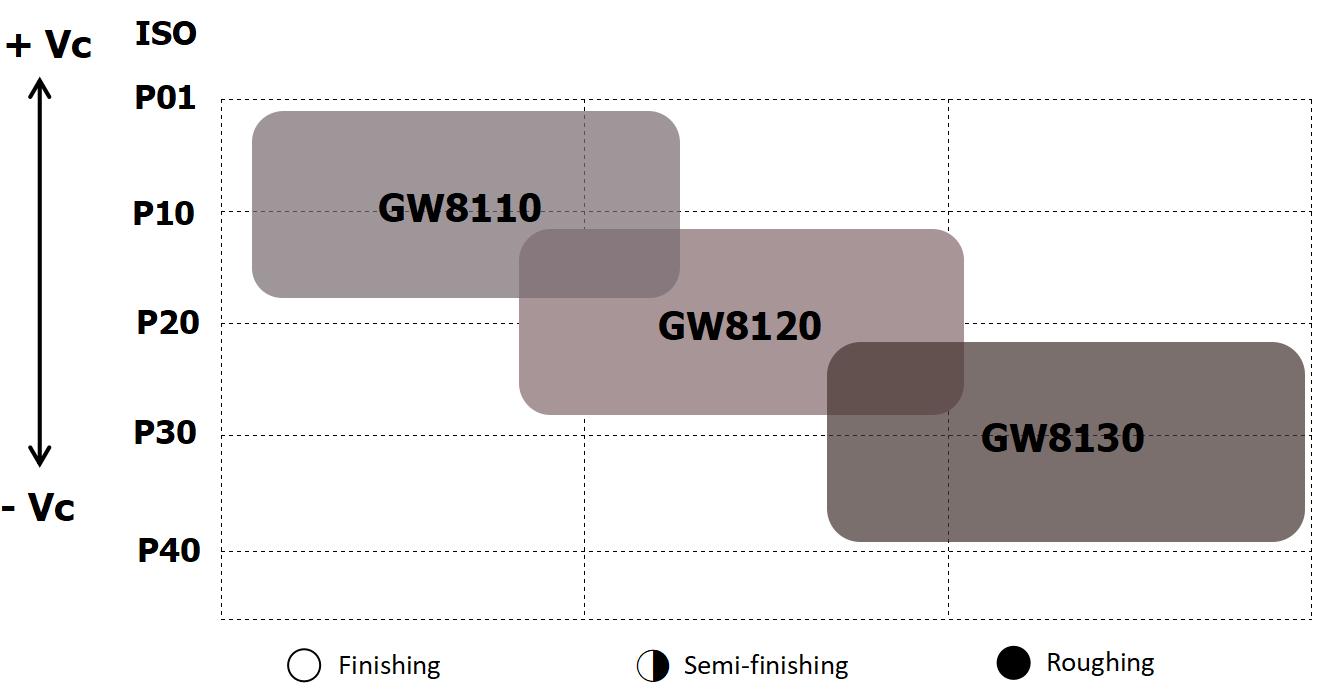

GW8110 、GW8120 and GW8130

Grades GW8110、GW8120 and GW8130 with its high wear tesistance and fracture resistance , this grade can withstand long periods of time in cut and is suitable for machining high hardness steel and hardened steel.

Benefits- Increased tool life provides reduced cost per component

- Improved process security ensures a predictable performance and less downtime

- High component quality

Features

- Ensures secure machining with a long and predictable tool life

- High metal removal rates and high reliability, even in challenging conditions such as complex tool paths and deep cavities

- Great performance in both dry and wet machining

Find your grade

Our steel insert grade assortment consists of coated carbide grades and uncoated cermets for various machining conditions.

GW8110

GW8120

GW8130

• High-hardness fine machining grades.

• Featuring a fine-grained matrix, offer both high wear resistance and fracture toughness.

• Applicable to finishing and semi-finishing machining of steel components, stainless steel materials, and high-temperature alloys.• High wear resistance.

• Applicable to milling processes of steel and stainless steel.• High impact resistance and wear resistance.

• Suitable for semi-finishing and rough milling processes on steel components, stainless steel materials, and cast iron.

About Chip breaker

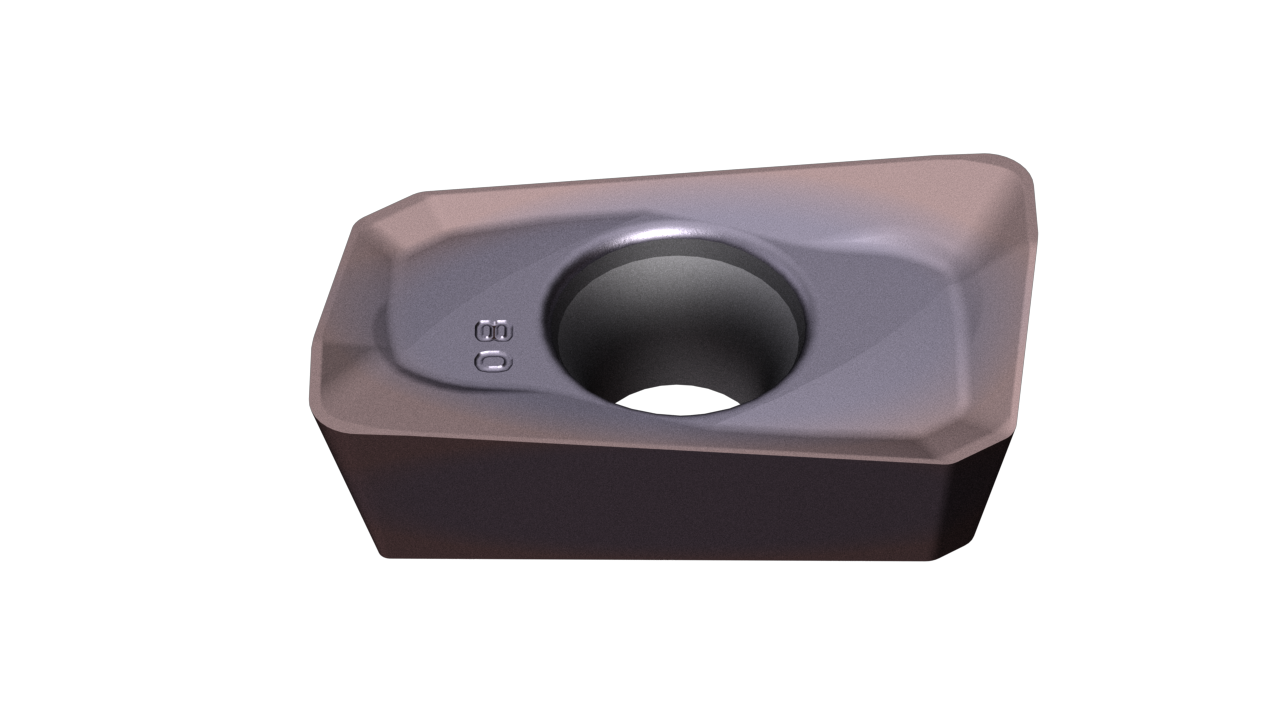

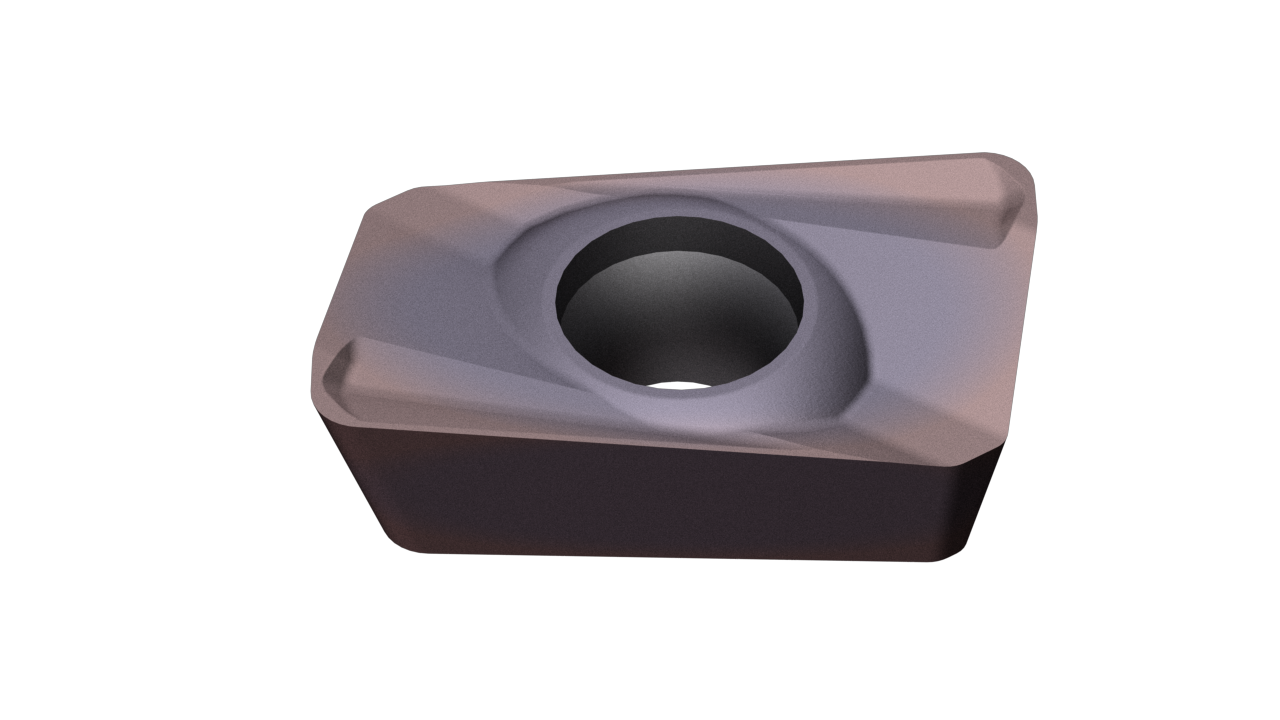

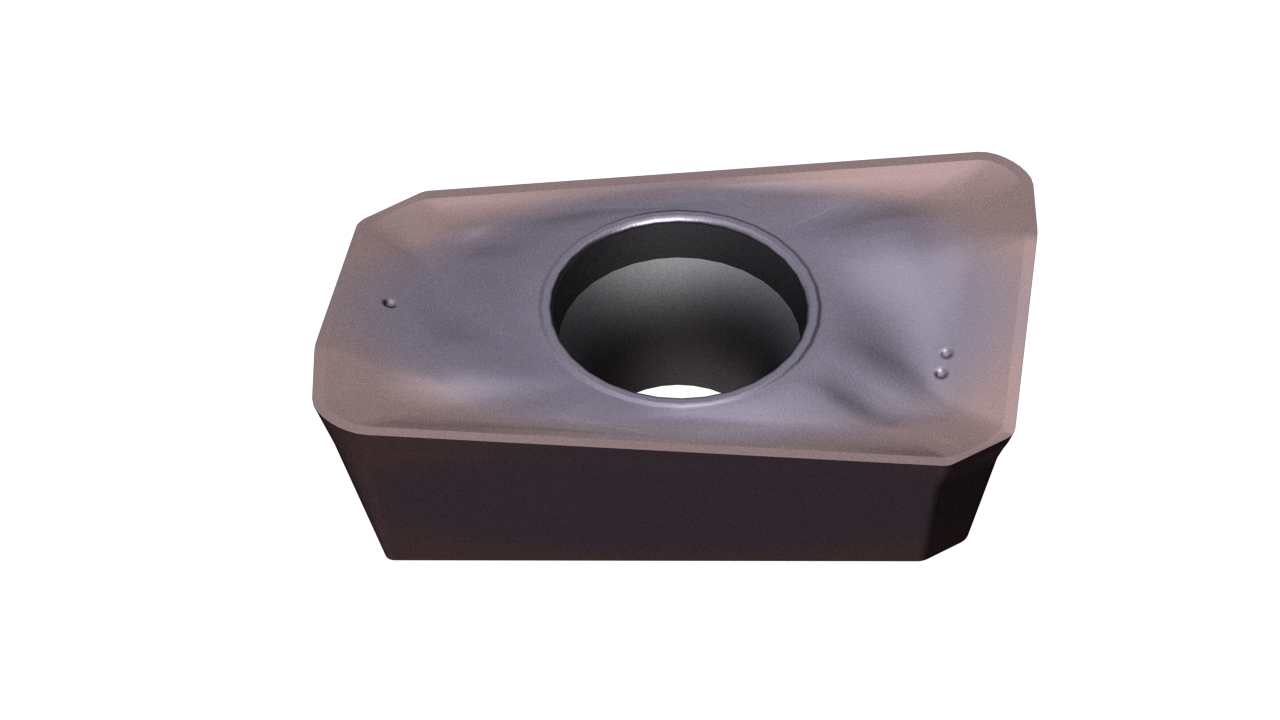

Chip Breaker

Illustration

Feature

Recommended Dosage

Feed rate

Cutting depths

M

·Sharp in structure with low surface roughness.

·Suited for finishing and semi-finishing operations .

0.3-0.5-1.5

0.2-0.4-0.8

H

·Suitable for roughing surfaces under harsh operating conditions.

·Suited for roughing operations .

0.3-0.5-1.5

0.2-0.4-0.8

DL

·Suitable for roughing surfaces under harsh operating conditions.

·Suited for roughing operations .

0.1-0.3-1.0

0.1-0.3-0.5

-

Customer ReviewsNo comments

USD

USD