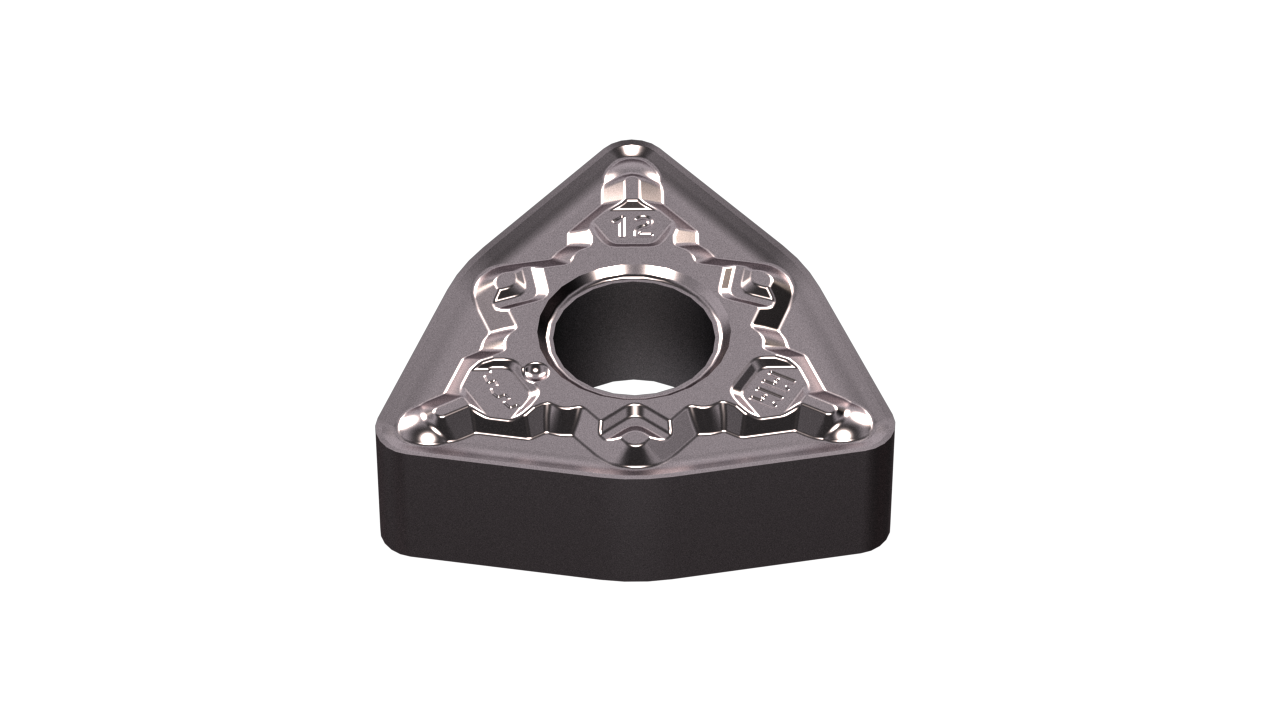

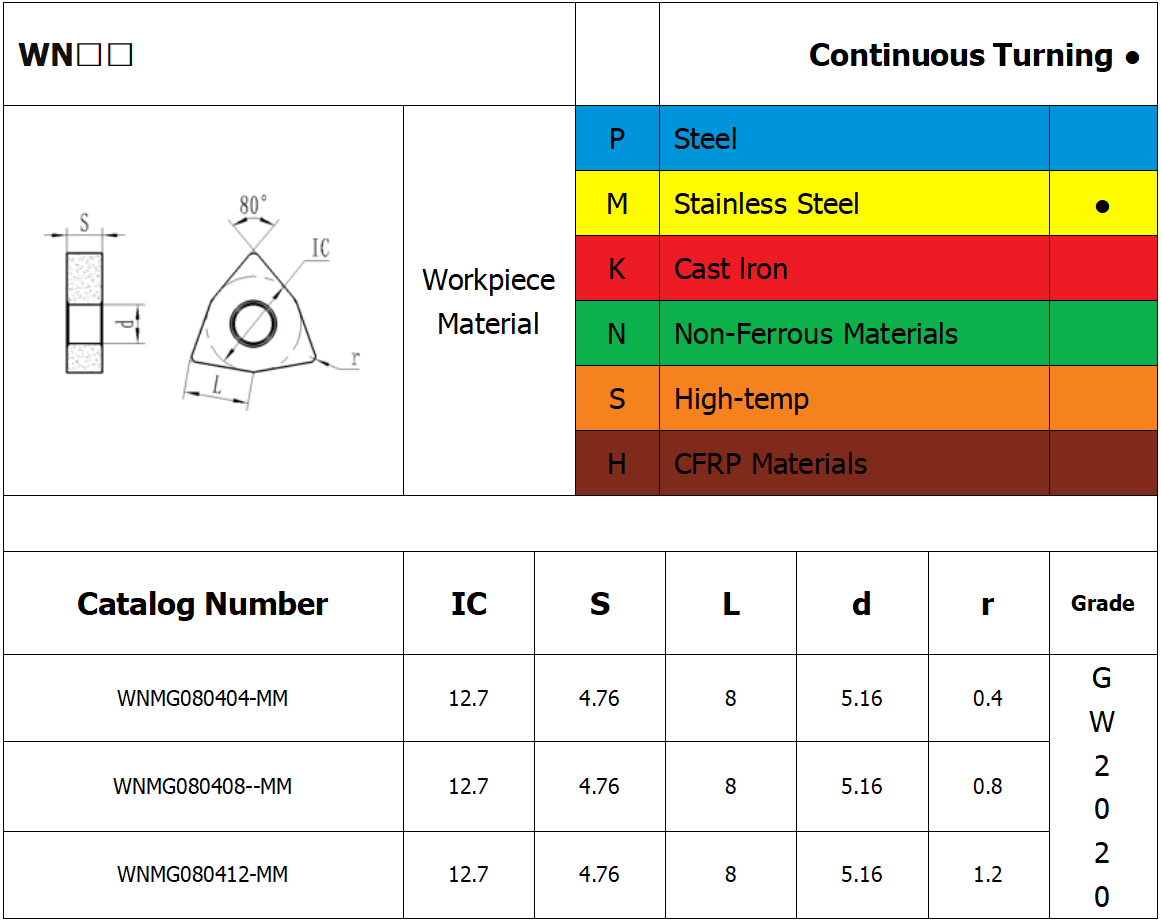

WN▢▢

-

Detail

Turning inserts and grades for stainless steel

Choosing the right insert grades for stainless steel turning is crucial, as these operations typically yield more friction and heat than many other materials. Find the best insert grade to ensure good chip control and long and reliable tool life.

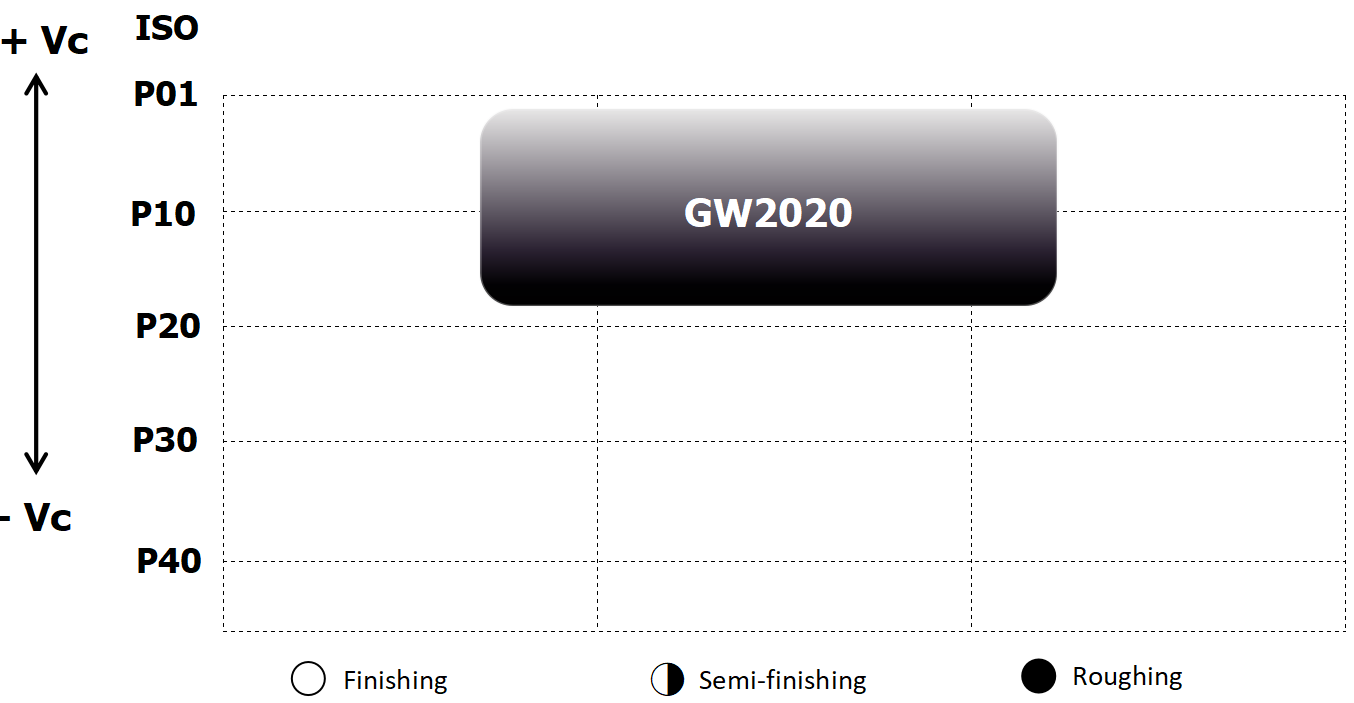

GW2020

From semi-finishing to roughing, this PVD-coated grade is the First Choice grade when turning stainless steel. With good resistance to thermal and mechanical shock, it provides excellent edge-line security for light interrupted and continuous cuts.

The latest turning grade GW2020 offers improved plastic deformation resistance and long tool life.Benefits and features

- High hardness substrate.

- Featuring a variety of rich flute configurations, achieving efficient cutting across multiple working conditions.

- High wear resistance.

- Good resistance to thermal.

Find your gradeOur hardened material insert grade assortment mainly consists for various machining conditions. We also have complementary grades. Use the information below to find the right grade for your production.

GW2020

• High wear resistance.

• It is specially designed for turning stainless steel.

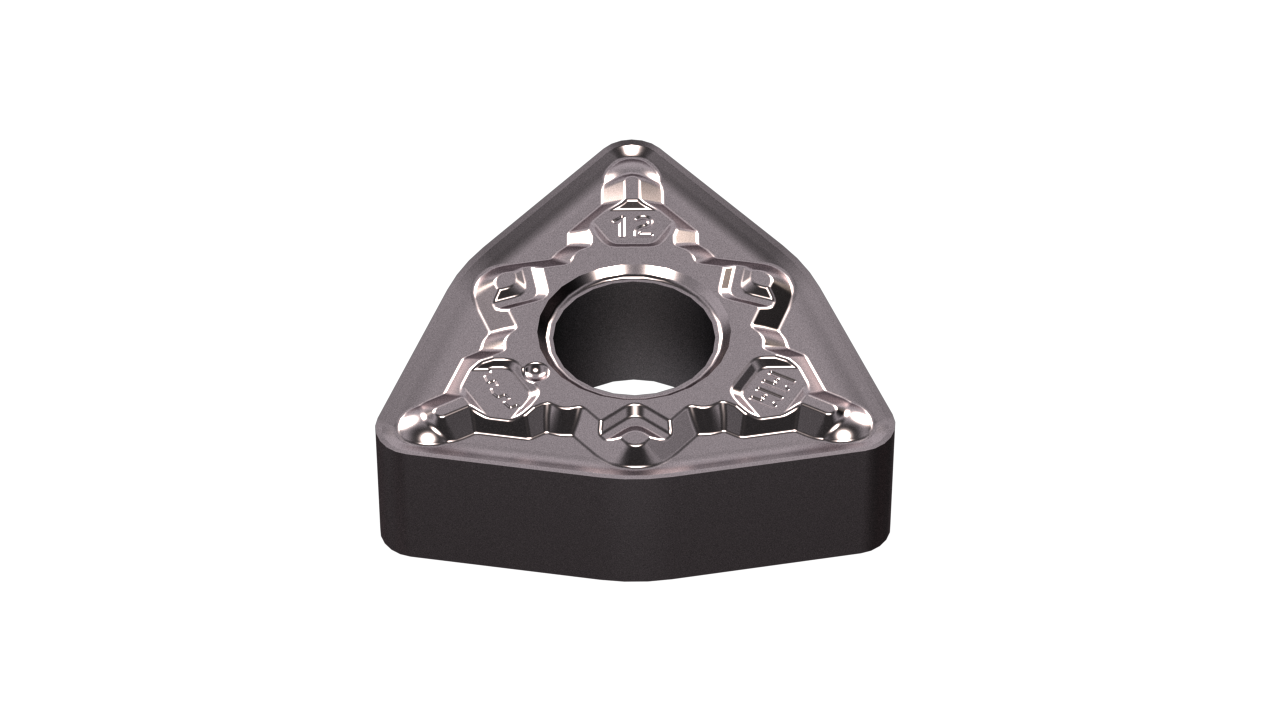

About Chip Breaker

Chip Breaker

Illustration

Feature

Recommended Dosage

Feed rate

Cutting depths

MM

·A double large rake angle design ensures a sharp tool with low cutting resistance and excellent chip adhesion resistance, while maintaining reasonable application strength.

·The chips are stable and do not wrap around the tool, allowing for no chip entanglement within the recommended processing parameters range, resulting in a bright workpiece surface.

·Suitable for semi-finishing of stainless steel.

0.15-0.20-0.25

0.8- 1.2-1.5

-

Customer ReviewsNo comments

USD

USD