TN▢▢

This price is for retail. For bulk orders, please inquire via email.

Quantity

-

Detail

Turning inserts and grades for hardened steel

Turning hardened steel calls for super-hard insert grades. Whatever your component or requirements for surface finish, find productive insert grades here that can withstand high temperatures and cutting forces and still retain their cutting edges.

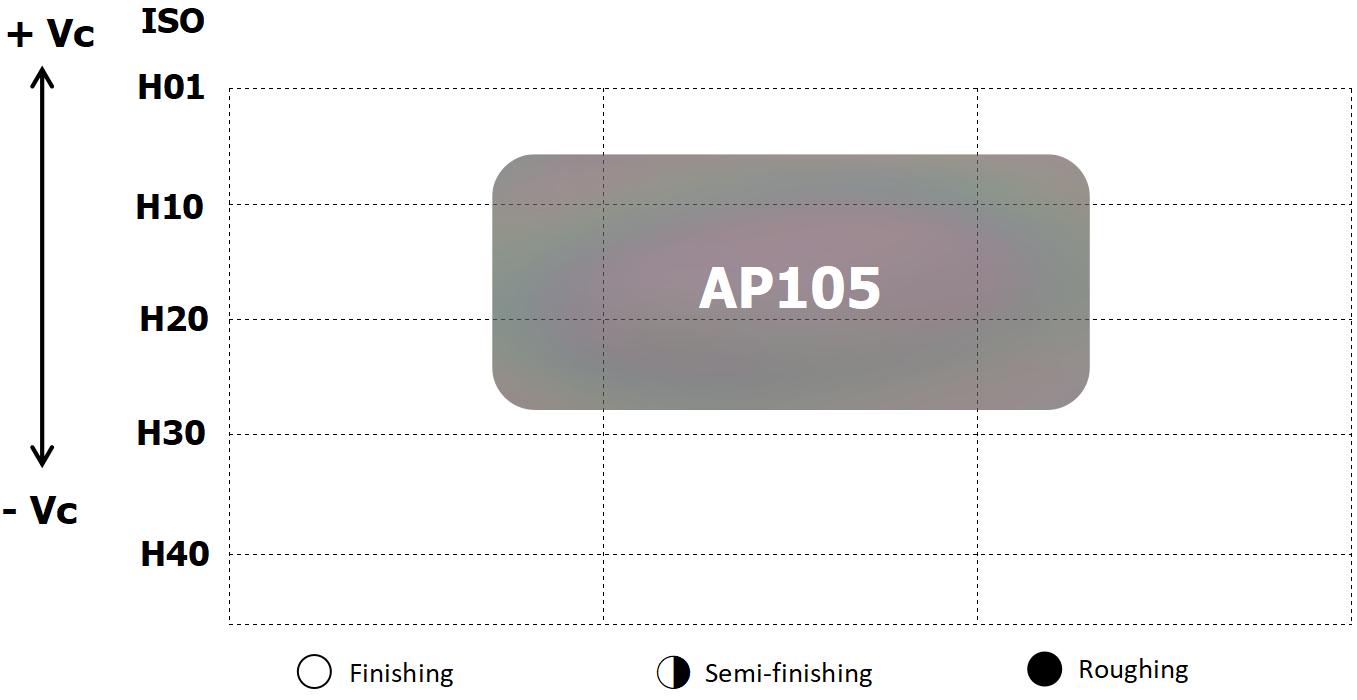

AP105

This grade is your first choice for case and induction hardened steels. With its medium content of boron nitride, it is suitable for light to medium interrupted cuts.

Benefits- Longer and more stable and consistent tool life

- Efficient and secure machining with good surface finish

- Consistent dimensional tolerances

- Lower cost per part when aiming for a one-cut strategy at high speed

- Improved wear resistance

Find your gradeOur hardened material insert grade assortment mainly consists for various machining conditions. We also have complementary grades. Use the information below to find the right grade for your production.

AP105

• High wear resistance.

• It is specially designed for turning hardened steel materials

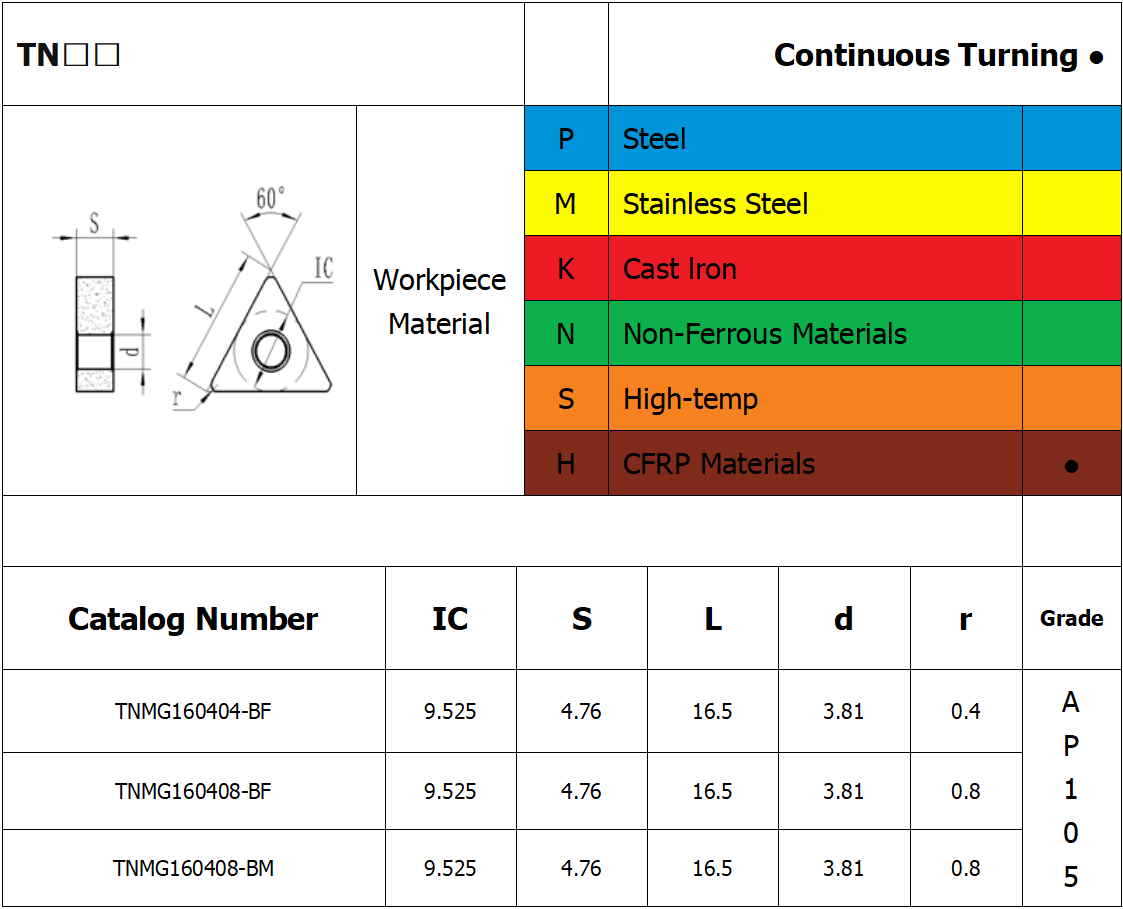

About Chip breaker

Chip Breaker

Illustration

Feature

Recommended Dosage

Feed rate

Cutting depths

BF ·A large rake angle design results in low cutting forces and good surface quality.

·Suitable for light interrupted finishing of hardened steels and other difficult-to-machine materials.

0.11-0.15-0.22

0.3-0.8-1.5

BM ·A dual rake angle design provides a wide chip-breaking range.

·Suitable for interrupted semi-finishing and roughing of hardened steels and other difficult-to-machine materials.

0.15-0.20-0.40

1.5-2.0-4.0

-

Customer ReviewsNo comments

USD

USD